UAB Energosa is dedicated to a customer support throughout all steel industry sectors, including manufacturing of a wide range of machined components too. We offer a high quality sub-contract machining services at competitive prices, with deliveries matched to customer’s individual requirements and most flexible regional delivery terms.

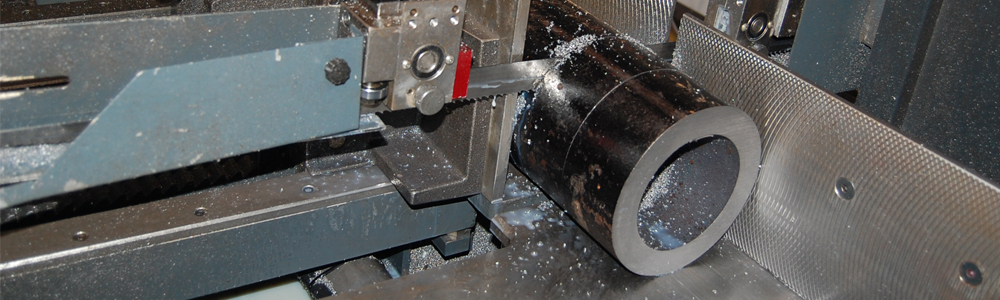

In house welding facilities give the advantage of producing fully machined welded structures to be directly erected on site. Combined facilities provide fully machined welded parts, mechanical assembly, CNC Precision Component Machining using advanced both CNC and manual Machines, milling, turning, CNC pipe drilling – boring - honing process.

Turning

Milling

Deep Hole Drilling CNC Machines

Thermal scope of services apply to thermal processing for metals and composites. It offers heat treating services, including hardening, quenching and tempering. Length of the detail not exceeding 1550 mm.

The paint shop facility is capable of painting various metals including aluminum, cast iron, machine parts and plastic.

Temperature controlled calibration, dust free clean workshops, reliable mainly EU origin machines, a multi-skilled and flexible workforce assure a short run small or large batch parts delivery on particular project needs. Extensive project management, design for manufacture, prototyping and cost reduction capabilities is vitally important to find always mutually acceptable solutions.

Continual improvement of measured processes allows to deliver outstanding reliability when final products are dispatched.